My four month adventure restoring a 1960s Nuffield tractor

Learning diesel mechanics from scratch

Original article posted here on 22nd June 2022

Why?

In 2017, after 17 years in the rental market, I embarked on the renovation of an 1800s farmhouse to fulfil a mortgage-free dream. Initially, I relied on the kindness of farming neighbours for the use of their heavy machinery. However, it was high time to source my own tractor. The problem? Tractors are expensive, and most were either overkill for my needs or out of my budget, considering all my funds were earmarked for renovation. The solution? I decided to spend four months restoring an old 1960s Nuffield 10/60 tractor myself. If done correctly, I would have a practically new tractor for a fraction of the price of anything I could buy second-hand. And, after the project, I would know how to maintain the tractor myself for future repairs - a win-win.

So, after sourcing a 1967 Nuffield 10/60 restoration project and not having a clue what I was doing, I began the mammoth task of stripping down the tractor and learning about 1960s engineering and diesel mechanics. Four months later, I turned the key and fired up the old tractor for the first time in nearly 30 years. Here's how I did it, with the help of Carly Mooney and a few other legends.

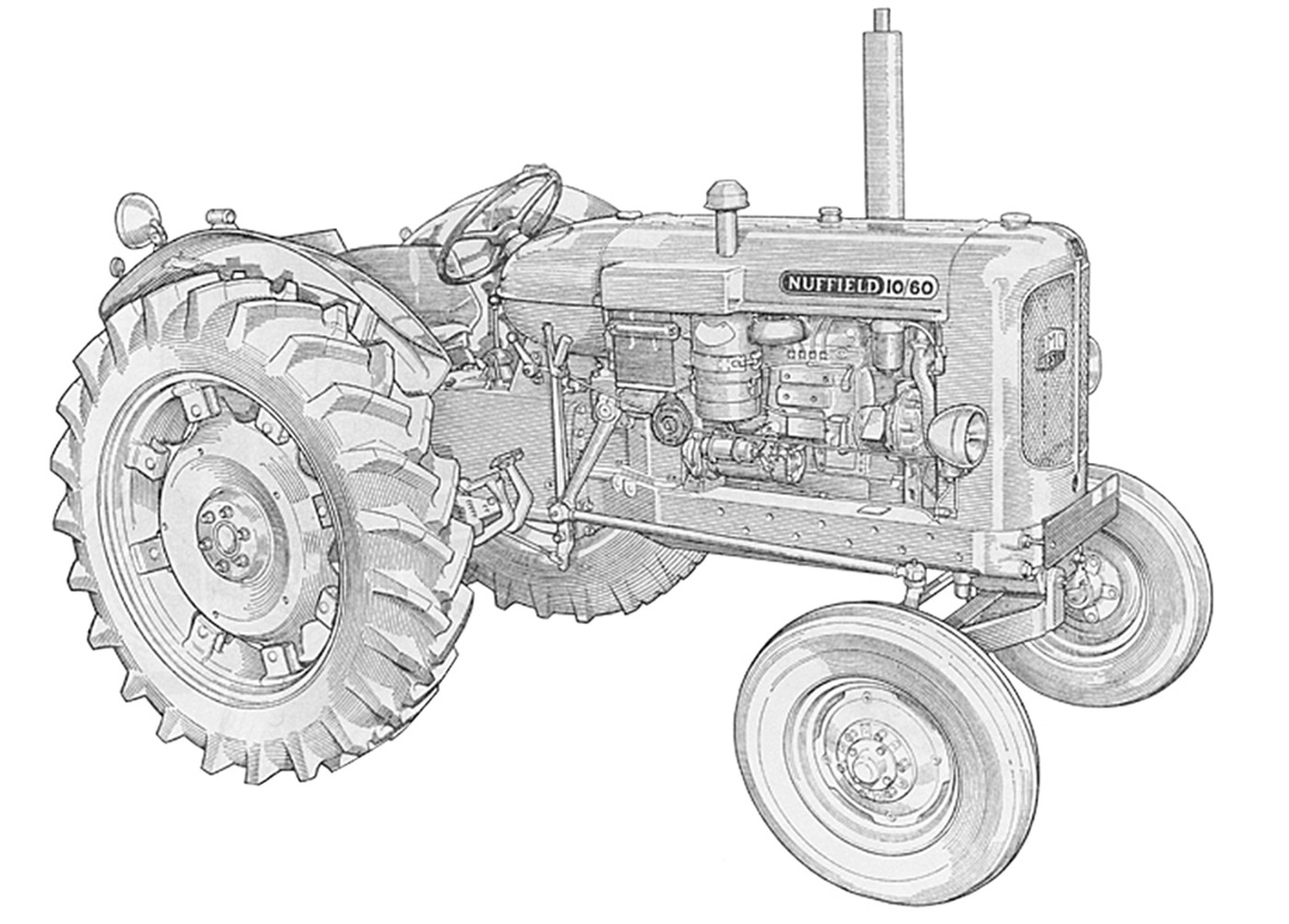

1967 Nuffield 10/60 tractor

Viscount (not the bickies), a Nuffield history lesson

This section is mainly about the history of Morris Motors and Nuffield, if you're not into that kind of thing just skip this and jump straight to the restoration.

Dr. H.E Merritt (Henry Edward Merritt) pictured left and Lord Nuffield (William Richard Morris) pictured right

The Nuffield tractor inherited its name from a village in Oxford called, you guessed it, Nuffield. It was all down to a man called William Richard Morris, born in 1877, who, after progressing from building bicycles and motorcycles, turned his hand to car manufacture and founded a company called Morris Motors in 1912. Over the coming years, Mr. Morris acquired or controlled a series of businesses including Wolseley Motors, The MG Car Company, and Riley Motors, to name but a few. Having been knighted in the 1920s, he was made Baron in 1934 and further elevated in 1938 when he took the title of Viscount Nuffield. Throughout the 1930s, Lord Nuffield became incredibly wealthy due to the success of his businesses. Then, in 1943, the first talks took place between Lord Nuffield (now aged 66) and Sir Miles Thomas (managing director of the Morris organisation) about agricultural production, during which basic specifications were drawn up for what would later become known as the "Universal" tractor. In 1945, when the British Government approached the organisation and suggested they design and manufacture an all-new all-British tractor to help with post-World War 2 recovery plans, the fate of the Universal tractor was cemented.

Designed by former David Brown tractor designer Dr H.E. Merritt (who had been involved with the design of the Centaur tank during the war), manufacture was to be assigned to the former Wolseley car factory in Birmingham. By May 1946, a prototype tractor had been produced, with a further 12 prototypes produced before the end of that year. However, due to steel shortages, mass production of the Universal didn't start until 1948. The agricultural division of the organization was given the namesake Nuffield, and so its first tractor became the "Nuffield Universal". Despite having a few initial setbacks, the Universal was hugely successful both technically and commercially. The tractor was produced in bright red-orange, officially referred to as "Poppy Orange". It was a large tractor for the time but compact in its design. A purposeful-looking, powerful machine displaying an alloy badge on either side of the bonnet proudly announcing the name "Nuffield Universal" and its arrival to the world. The fact that the tractor, and its successors, appeared unchanged for nearly 20 years despite constant upgrades, engine changes, transmission changes, and more is a testament to the brilliance and simplicity of the original design.

Morris Motors merged with the Austin Motor Company, its long time rival, in 1952 to form the British Motor Corporation (BMC). The future of Morris Motors would be determined by BMC chairman, Leonard Lord, an ex Morris Motors MD who left for Austin Motors in 1936 promising to destroy Morris. In the end, Mr Lord retained the Morris name and Nuffield dealer network but it was clear that BMC’s interests were firmly invested at the Austin factory at Longbridge. Mr Lord didn't destroy Morris Motors as he had initially planned but he did let the marque fade and, after years of neglect, the Morris Motor company quietly passed away in 1984. Lord Nuffield was chairman of BMC for its first year until he retired in 1952 at the age of 75. Then, 10 years later, on the 22 August 1963, age 85, Lord Nuffield passed away, 21 years before the end of the organisation he had started from a shed in Oxford. William Richard Morris was, without doubt, Britain's answer to Henry Ford and, from humble beginnings, building bicycles, his innovation and subsequent amalgamations helped deliver marques like Morris, Nuffield, Leyland, Marshall, Jaguar, Triumph and Land Rover as well as icons like the Morris Minor, the MG Midget, Triumph Spitfire, Range Rover, the Mini and more.

In 1968, BMC was amalgamated with the Leyland Motor Corporation which also owned Standard Triumph and Rover to become British Leyland. Tractor production continued under the Nuffield name until 1969 when the tractors were renamed as Leyland and the previous poppy orange changed to the new two-tone blue Leyland corporate colour scheme. In 1981, the Nickerson group purchased the tractor operations of Leyland. The current Leyland tractor range was re-branded as Marshall and relaunched with a new yellow colour scheme (meaning there were identical tractors but with different names and colour schemes in circulation at the same time). Then, in 1985, a former dealer, John Charnley and Sons in Lancashire, purchased the design rights for Marshall (but not the brand name) and all tooling, machines and equipment, as well as spare parts. This would be the last chapter in the colourful Nuffield tractor history that essentially started in 1912 and came to an end in 1985.

The Restoration

Step one, what have I got?

Firstly, I needed to investigate the condition of the tractor in a little more detail. That meant looking at the major mechanical areas and investigating whether they were restorable, if they would need to be fully rebuilt, or indeed if they needed replacing. Was the engine, gearbox, back-end, and clutch in good condition? Yes, yes, yes, and no. Three out of four wasn't bad; in fact, it was great. I tracked down a local diesel mechanic at this early stage to point me in the right direction, and we figured out that the engine was in good condition, the cylinder compression was good, both the high and low transmission gears weren't chewed up, the back-end lift pump seemed good, most seals and even the PTO were in great condition, all things considered. Getting away with just a few repairs to the clutch meant I was off to a flying start.

Step One - Grow an incredible, majestic beard

Planning

Knowing I had a good foundation to build on was important. Second-guessing that throughout the project wouldn't have helped the end result. Now, I could do what I do best, plan. I needed to get my hands on the original Nuffield 10/60 workshop manuals and, more importantly, the parts manuals, and familiarise myself with every inch of the tractor. This would prove a little difficult as much of the tractor was missing. Reference photos online and YouTube videos helped. I also, luckily, had access to a Nuffield 4/60 at neighbouring Ballybeg House wedding venue. So, I had full access to a Nuffield that was basically the same tractor (just a different gearbox). For a complete newbie Nuffield mechanic, having a reference point of a complete tractor helped enormously.

Trespassing at Ballybeg House, Nuffield history books and a workshop manual 2.5 feet thick

I also needed to figure out which parts I could rescue, which parts I could fabricate myself, which parts I could buy new and finally which (difficult) parts I would need to go on the hunt for i.e. that were not available to buy new. Finding a list of suppliers was next on the agenda and where better to start than with Charnleys in Lancashire who, if you remember from earlier, bought the design rights and spares from Marshall. I hit the jackpot with my first phone call to Charnleys and an incredible human, called David, would become my new best friend for the next four months, sharing not only his incomparable knowledge about Nuffield parts but also the incredible history of the marque. There were a few vital things David helped me discover about my Nuffield but he also ignited a curiosity about the history and the people who built this brilliant machine.

The first curveball

As I examined the tractor more closely I almost quit before I began. I had all of the parts and workshop manuals but even with the pretty exploded pictures and drawings I couldn't make sense of anything. Nothing was where it was supposed to be. Well, kinda; some things were where they were supposed to be, some weren't and some had been purposefully removed. I was being hardcore gaslighted by this mofo. First, I blamed 1960s documenters for not recording correct measurements, parts and locations. Then, I took a swipe at the illustrators. But eventually, with the help of David at Charnleys, it came to light that the engine was not a 10/60 engine at all but an engine from the later 4/65. Both good news and bad news.

Nuffenstein's 4/65 engine and shoehorned fuel pipes

The good news was I had a much better and more modern engine with five more horsepower (every horse counts). The fact the engine was in great condition and not worn out, now also made sense as it probably hadn't done much farming work. The later 4/65 engines also had a harmonic balancer which meant they were smoother, quieter running and had less engine vibration than older engines. That was the good news. The bad news - everything was shoehorned. While the 10/60 and 4/65 engines weren’t from different sides of the globe they weren't exactly the same either.

But as my dad used to say, "Knowing the problem is half the fix". So, with that ringing in my ears, I went back to the drawing board, found new workshop manuals and documentation and figured out how I was going to restore and decipher the half 10/60 half 4/65 Frankenstein tank-tractor. Water hoses for example were on the wrong side and there were no off-the-shelf solutions so I would need to design my own hose system making sure it would clear all moving parts, fans, fan belts, pulleys and electrics. It was a similar situation with the diesel line and diesel filters, I would have to design, bend and solder my own diesel lines to suit Nuffenstein.

It started with a starter

Finally, I was off. Time to get my hands dirty. Where better to start than with the starter. There's no point having a fancy tractor if you can't start it. That's where I ran into the next small problem. Nuffield starters were difficult to find and the ones I could find were expensive. I didn't want to blow my budget right out of the gate. However, cost wasn't the biggest issue. Most suppliers required customers send them an old starter before they would dispatch a new/reconditioned motor. I didn't have an old one, just an empty hole in the side of Nuffenstein. So, I was in a bit of a pickle. Enter Rick Cobley from Leicestershire, a fountain of knowledge for all things Nuffield. Think "The Oracle" from "The Matrix" but with a Nuffield twist and less kung fu. I found Rick on YouTube and, by chance, happened across one of his videos explaining how to take a much cheaper and more widely available ford starter motor and, using an angle grinder, modify it to fit on a Nuffield. Just what I needed.

And so it begins, the first delivery of many. A shiny new Ford starter ready for the grinder.

What goes fast must slow down

I was determined to improve upon the infamous Nuffield dry braking system. As well as improving the braking system, I also planned on adding a roll-bar, just in case. So, the next logical step was to tear down the brakes. As it turned out, it was all pretty straightforward and I soon came to the conclusion that replacing everything was the best option. New discs, balls, springs, rubbers and most important of all, seals for the main axle shafts to keep oil away from the brake disc/pads. It seemed every Nuffield owner and expert agreed that oil and rust were the biggest enemies of the dry braking system. So I had three goals; all new bits, keep the water out and keep the oil out. Seals on the back axle shaft to keep the oil out and to keep the water out, new rubber boots, as well as new gaskets for the brake housing covers.

An original BMC parts packet in my first order from Charnleys!

I also felt quite smug having a secret magic weapon to improve on the 1960s engineering standards. Experts everywhere warned not to oil the braking system in any way, not even the springs. The problem with oil is it stays wet in order to provide lubrication and wet oil runs, attracts dust, turns to gunk and is just generally bad for a dry braking system. However, on the flip side, not lubricating the balls and springs in the housing means they rust which then in turn causes the brakes to stick. If one brake sticks and the other doesn't, the tractor could potentially turn over, not good. Catch 22? I think not. Enter my secret weapon. A spray can of Lidl's finest "Dry Graphite Spray Lubrication" that I had been using for my mountain bike. Lubrication without the wet mess. Job done, where's my crown?

Feeling like the cat that got the cream I quickly reassembled everything. But, when I inserted my four brand new brake discs in their housings, the housing covers were not anywhere near closing. If I had forced them the axle would have permanently braked on. Take my crown back, off to the forums again with my tail between my legs. I soon found out that proper Nuffy mechanics never install four brand new discs in a Nuffield at one time. Apparently one worn and one new for each side was the way to go. Sometimes, the book is wrong and good old fashioned experience wins out.

Your imperial highness

As the tear down and mechanic-ing continued I found myself scratching my head again. Either my spanners and sockets had shrunk in the sun or there was something else afoot. The spanners and sockets didn't fit fifty percent or more of the nuts and bolts. I put a few curses on Dr. Merritt but after some research I realised that Nuffenstein was even more of an abomination than before. You see our beloved Nuffenstein 10/65 tank-tractor was built at Bathgate in Scotland in 1967. It was one of the last of the 10/60s, as production had ceased by 1968 and moved onto the next model, the 4/65. But, in 1965 a formal government policy to support metrication was agreed, which meant that the Nuffields of the time used both imperial and metric nuts and bolts. Given that I'm not 100 years old, all of my tools are metric so I needed to figure out all of this imperial malarkey and tool up accordingly. A few key ring spanners and a good set of sockets were all I needed to save my knuckles.

Taking it up a gear

Next on the agenda was the clutch, having put it off for long enough a new pressure plate was required. Luckily, with the Nuffield design, the tractor (unlike most modern tractors) didn't need to be split down the middle. Just pop off the bell housing and go to work. Easy, right? This was probably the most difficult job of the restoration but I had lots of resources to pull from and all parts were available to buy new. Thankfully, all this area of the tractor was pure 10/60 territory so I went back to "going by the book". It took a few days to complete and I would have to wait until I had the tractor running to know if I'd messed it up or not.

Methylene chloride

No, I didn't degenerate into Walter White along the way and discover a new business opportunity. Methylene Chloride, also known as Dichloromethane, is a brilliant but also horrible and potentially lethal chemical that has killed many people from improper use. It is highly regulated and banned in many places. The Obama administration proposed a ban on methylene chloride in early 2017, saying it posed "unreasonable risks" to human health. The European Union is also cracking down on paint strippers using the substance. Not only can it suffocate humans in poor ventilated areas but it is also deemed to be a probable cancer-causing agent.

I managed to get my hands on some and it is, hands down, the most dangerous substance I've ever handled. So, on a nice fine day with a strong breeze I suited up with an appropriately rated mask, goggles, rubber gloves, hat, rubber boots and my favourite rain suit and I covered the tractor with this killer sludge so it could eat away Nuffenstein's nearly sixty year old enamel paintwork. I had considered sandblasting, a much easier, faster and safer alternative, but an old tractor guy advised me against that route. "An easy option," he told me, "But you will regret it when your gears start to grind. You will have a shiny tractor with no gearbox." He was a small man; old, with a crooked stick and a peaked hat who spoke very few words. Kinda like an Irish tractor Yoda. From the conviction of his words you could easily tell they were wise and learned through experience so I dared not ignore them.

But even after two coats of the Walter White killer sludge there were still stubborn patches of poppy orange that wouldn't budge. Time for stage two which involved another of Lidl's finest, a Parkside cordless grinder, about one hundred flap sanding discs and a week of bringing Nuffenstein back to bare metal in preparation for the undercoat. Time was of the essence as bare metal oxidises fast. I needed to get the red oxide undercoat applied on the double.

Painting

Having stripped the tractor of its old paintwork I needed to get the first undercoat of red oxide paint on ASAP before everything began rusting up. Because I was in an open air shed I needed two days that were warm, above 15 degrees preferably, but calm with no breeze, so dirt and dust particles wouldn't ruin my fresh paint. Eventually, I found a perfect run of four days with the last two days having the perfect conditions for spraying. I used day one and two for Methylene Chloride, day three for undercoat and day four for the final top coat. Investing in an air compressor system wasn't an option so after throwing some ideas back and forth I settled on an electric sprayer. The idea was a little unorthodox and many tractor enthusiasts would scoff at my plan but having seen the results of a small German Wagner sprayer I knew it would be good enough for my needs.

Next up was finding a paint supplier and the correct paint codes. There are a few different paint codes floating around for Nuffield, with many of them straying a little too close to Massey red. I wanted that original bright red-orange. Props to Foxs in Tullamore. Of course being a designer I had to leave my mark and make some small improvements to the design, pretentious much? Originally, the front grills were poppy-orange but I changed them to black - much better. Also, the radiator cooling fan was originally bright yellow but a little bit of green I thought was a nice touch seeing as the tractor had spent its entire life in the Emerald Isle. I'm sure Lord Nuffield wouldn't mind.

Above: Two coats of red oxide undercoat to keep the rust away.

Above: First coat of Nuffield Orange.

Above: Top coat of Nuffield Orange.

Floor-pan fails

Probably the biggest misstep of the project were my fabricated floor-pans. Floor-pans were not available to purchase new or even second-hand online. I'd exhausted all of my local contacts to no avail so I decided to fabricate them myself. Terrible idea. After much measuring, bending, cutting, drilling and welding I stepped back from my creations. They were indeed floor-pans and they would stop Nuffenstein occupants from being mangled under its unforgiving wheels. But, sometimes, there are just no substitutes for the real thing. After a weeks work I ditched the floor-pans and went searching again. I eventually found a little known tractor breaker "down the country" who had an old scrapped "Universal" buried under a mass of briars and scrub. They weren't a perfect fit, a few holes would need to be drilled, but they were good enough. Now, rather than curse Dr. Merritt, I lauded him for keeping the tractor design essentially the same for almost 20 years. What a guy. I had an old manager once who used to, so eloquently, say, "Learn fast if something isn't working and move the f**k on." What he said.

Newly sourced floor-pans and step from a much older Universal and a brand new seat assembly.

Dropping the sump

A sump is like a big metal basin that's bolted to the bottom of all internal combustion engines. It basically holds all the oil from the engine when the engine isn't running. It's also the place where the usual tiny metal shavings from engine wear and tear typically end up. If you drop your sump and find chunks of gears and pieces of metal then you have a problem, an expensive, time-consuming problem. Although I was confident the engine was okay there's always that chance of finding a chunk of metal in there so I was absolutely dreading dropping the sump. I smiled like I never smiled before as I ran my fingers through that 30-year-old oily sludge - not one piece of metal, not even a shaving. So I cleaned it up, dropped on a new gasket with lots of gasket cement, evenly tightened the bolts (that's important) and done. I popped on a new oil filter and rings then filled to the mark with oil immediately afterwards. Time for a coffee and a little victory dance. Don't judge me.

The sump all cleaned up and new gasket versus old gasket

Water pipes

Thanks to the 4/65 engine, the off-the-shelf water pipes for either a 4/65 or a 10/60 wouldn't work in my situation. So, after a few careful measurements and creative phone calls with David in Charnleys we were sure we had a solution that would work perfectly. Of course it worked, I didn't doubt us for a second.

Before and after with new pipes especially designed for Nuffenstein and a touch of the Emerald Isle on this British icon.

Diesel, diesel, diesel

On to the second last big job of the project. Getting diesel from the tank into the engine and all the pipes, stops, joiners, filters, sediment bowls, lift pumps, injector pumps and injectors in between. On appearance the diesel tank looked like it was in great condition however turning it upside down told a different story. There were pin holes in the bottom of the tank and surface rust covering the entirety of the inside. I needed to find someone to repair the pin holes and I would remove the interior surface rust myself.

Some owners swore by sealing the inner tank with a paint like substance that dried into a hard coating and covered the interior metal of the tank. However, mixed reviews and horror stories about this substance peeling off and ruining fuel lines steered me clear. Instead, I soaked the inside of the tank in vinegar to get rid of the surface rust then rinsed it out and filled it up with ten litres of EVAPO-RUST, turning it every few hours so the entire tank was treated. After that, I power-washed the tank and dried it out with a heat gun before rinsing the entire tank with diesel ensuring total coverage. The trick with cleaning an old metal tank like this was to not leave it too long without diesel so I planned this as one of the last jobs right before connecting up the fuel lines.

Keeping a good level of diesel in an old metal tractor tank helps stop rust developing again. I also added a clear in-line fuel filter just before the sediment bowl which was a cheap and easy way to stop bad things getting through to the engine components. And, because the filter is clear it means I can keep an eye on the diesel quality into the future. There is another filter in the tank which most experts recommended removing to "improve" the tank and fuel system but I ignored that advice. You can never have too many filters. It's easier to fix a clogged filter than a banjaxed engine.

The long and winding journey of diesel from tank to engine.

Lights, Nuffield, action!

It's hard to explain the combined feeling of dread and excitement as I came to the last few days of the project. I couldn't wait to turn the key but what if it didn't work? What if all this work, effort and money spent had been a complete waste that went up in a single big puff of black 30 year old Nuffield smoke? But, as the shiny Nuffield clocks slotted perfectly into the newly painted dash, oh my, oh my.

The electrical side of things was always a concern. Most seasoned tractor mechanics will admit to knowing very little about wiring looms or electrics and, while the Nuffield wiring was relatively basic, the entirety of the loom needed to be replaced. The old-school dynamo system also needed to be changed over to a more modern alternator setup. This meant reversing the "earth" or polarity of the tractor which I had no idea how to do. Also, most all of the electrical components including lights, switches, wiring, connectors etc... were missing. Enter Padraic Brewster from Brewster Electrics in Longford, a man with the patience of a saint who doesn't believe in next day delivery. Padraic, having realised that mechanics are not electricians, came up with with an ingenious, but simple, solution of numbering the ends of the wiring loom and providing an A4 sheet explaining each number and letter. Brilliant! Exactly what I needed and the final part of the puzzle. Good man Padraic, they'll write books about ya.

Fire it up!

It took four months to learn all the things I needed to learn, source parts, fabricate parts and bring the Nuffield back to its former glory. I couldn't have done it without the help and support of Carly and lots of other incredible humans who were kind enough to share their time and knowledge. It was a great, but crazy, time where I met some awesome characters and smelled like a rusty diesel tank 24/7. I learned much about the history of Morris Motors and Nuffield, along with the mountain of technical and mechanical things, but probably the most valuable lesson was an old war slogan I found during my research into post war tractor production, "Keep Calm And Carry On". There were good days and bad during the restoration but that stuck in my head throughout and helped guide me through. Here's the end result.

Props

No person is an island. This is especially so when in unfamiliar territory. A sincere thank you to all these people who helped, had an abundance of patience for stupid questions and kindly shared their wisdom and knowledge.

Paul Grace

Rick Cobley - Rick's YouTube, Nuffield Tractor Forum & Facebook Group

P.J.

Seamus Dempsey

One last thing...

One of my favourite things about this project was unearthing some of the old 1940s, 50s and 60s Nuffield advertisements. Absolutely beautiful, incredible work albeit with a smidgin of misogyny and some questionable font designs. Here are some of my favourites.

Above: By far and away my favourite for so many reasons.

Above: Dapper gentlemen.

Above: Farmers were fierce well turned out back in the day.

Above: That font though.

Above: Simple, to the point, instantly recognisable. Love it.

Above: Gorgeous illustration.

Above: Bring back the days of farming in suits and hats, what a time.

Above: So adventurous with fonts.

Above: An absolute steal at only 567 bob.

Above: The font bandit strikes again.

Above: "A most completely equipped Tractor"

Above: Greater! Smoother! Easier! Better! "It's our best tractor yet - Jony Ive"

← Writing